Summary

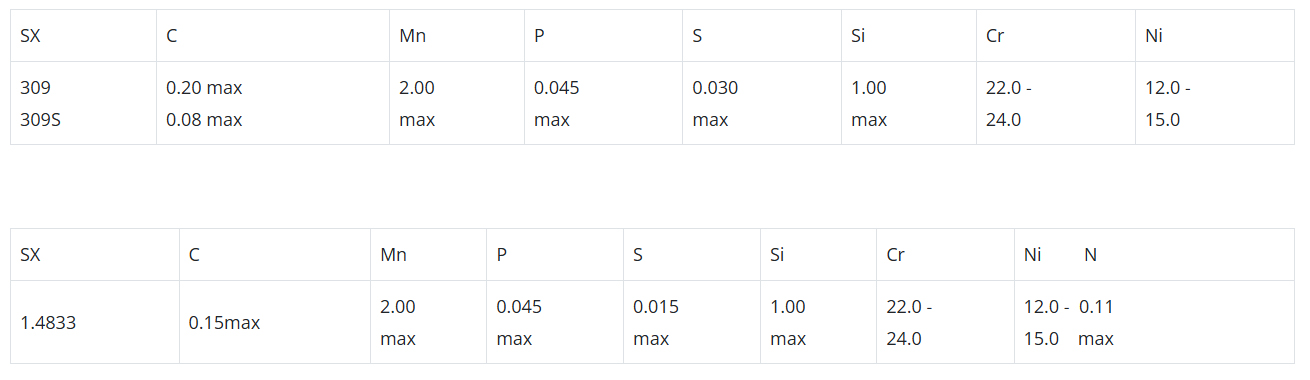

SX 309 is a highly alloyed austenitic stainless steel known for its excellent oxidation resistance, high-temperature strength, and creep resistance. The lower nickel content of SX 309 enhances its resistance to sulfur attack at elevated temperatures. This material is tough, ductile, and easily fabricated and machined. SX 309S is the low-carbon version of SX 309, recommended for applications where sensitization and subsequent corrosion by high-temperature gases or condensates during shutdown may be a concern.

Typical Applications

SX 309 / 309S is exclusively used for its high-temperature oxidation resistance. It is common for SX 309, SX 310, and SX 321 to be used together in the same equipment to handle various temperature regions effectively.

Typical Properties in the Annealed Condition

The properties quoted in this publication are typical of mill production and, unless otherwise stated, should not be considered as guaranteed minimum values for specification purposes.

Mechanical Properties at Room Temperature

- Tensile Strength: ≥515 MPa

- Proof Stress (0.2% Offset): ≥205 MPa

- Elongation (Percent in 50 mm): Longitudinal: 35% Transverse: 25%

We have products:

Control line tubing in oil and Gas Well; ASTM A403 Stainless Steel Pipe Fitting Of Elbow 90 Degree LR; SS310 / TP310S 48.3 * 4 * 6000MM Stainless Steel Seamless Pipe Annealing / Pickling; ASTM A312 Stainless Steel Welded Pipe TP309S / S30908 , 14 Inch Sch40; 309SUS Stainless Steel Welded Pipe 14 Inch Sch40 , Size 355.6mm x 11.13mm x 3305mm; TP309S Welded Stainless Steel Pipe 14 INCH SCH40 , 355.6mm x 11.13mm; 9.53 * 0.89MM Super Long Coiled Tubing , 300 Series Stainless Steel Material , ASTM A269 / A213; ASME B16.5 Flanges Pipe Fittings , Blind 150LB RF; WP310s / 309s Stainless Steel Concentric & Eccentric Reducer Pipe Fitting; ASME B16.5 DN300 Stainless Steel F309S / F310S Welding Neck Flange; DIN2566 1.4306 Stainless Steel Threaded Flange; F304 / 304L Stainless Steel Threaded Flange, Class 300; Stainless Steel Flanges Pipe Fittings 300 Series Raw Material ISO 9001 / PED; S30908 / S31008 8mm Stainless Steel Bright Annealed Coiled Tubing; 1 / 2 Inch Sch10s Small Diameter Stainless Steel Welded Marine Multi-core Tubing; ASTM A213 TP309S / 310S Stainless Steel Welded Multi-core Coiled Tubing For Marine; ASTM A213 / ASME SA213 ERW / EFW Stainless Steel Welded Tube With Bright Annealed Surface; 3 / 8 Inch TP309S / 310S Small Diameter Stainless Steel Bright Annealed Welded Tube; DN150 TP309S / 310S Austenitic Stainless Steel Big Size Pipe; 3 / 4 Inch TP309S / 310S Stainless Steel Heat Exchanger U Bend ERW Welded Tube; ASTM A269 / ASME SA269 Small Diameter 1.4306 / 1.4404 Stainless Steel Heat Exchanger Welded Tube; 16 Inch Sch40 ASTM A358 TP309S / 310S Stainless Steel Double Welded Pipe For Transportation; TP309S / 1.4833 DN250 Big Size Stainless Steel Double Welded Pipe For Transportation; Stainless Steel Sanitary Tube, ASTM A213 / A269 TP309S / 310S For Chemical Industry; 1 / 2 Inch Sch80s ASTM A269 Bright Annealed Stainless Steel Sanitary Tube; S30908 / S31008 Stainless Steel Sanitary Tube With Bright Annealed Surface For Gas And Fluid; 18SWG TP309S / 310S Stainless Steel Precision Tube, ASTM A213 Seamless Tube; ASTM A213 / A269 TP309S / 310S Stainless Steel Seamless Instrument Tube With Cold Rolled; ASTM A213 / A269 TP309S / 310S Stainless Steel Seamless Instrument Tube With Cold Rolled; ASTM A269 / ASTM A213 TP309S / 310S Stainless Steel Seamless Instrument Tube For Transportation; ASTM A312 / ASME SA312 TP309S / 310S Industrial Pipe For Chemical Industry; TP309s / 310s Stainless Steel U Bend Heat Exchanger Tube, ASTM A269 Welded Tube For Boiler; TP309s / 310s ASTM A213, Stainless Steel Bright Annealed Tube 6.35 * 0.71mm; For Boiler ASTM A213 Stainless Steel Seamless Heat Exchanger Tube; Stainless Steel 309S/310S EPQ Wire Drawing Wire High-resilience;