Skip to content

Refractory 26

Features:

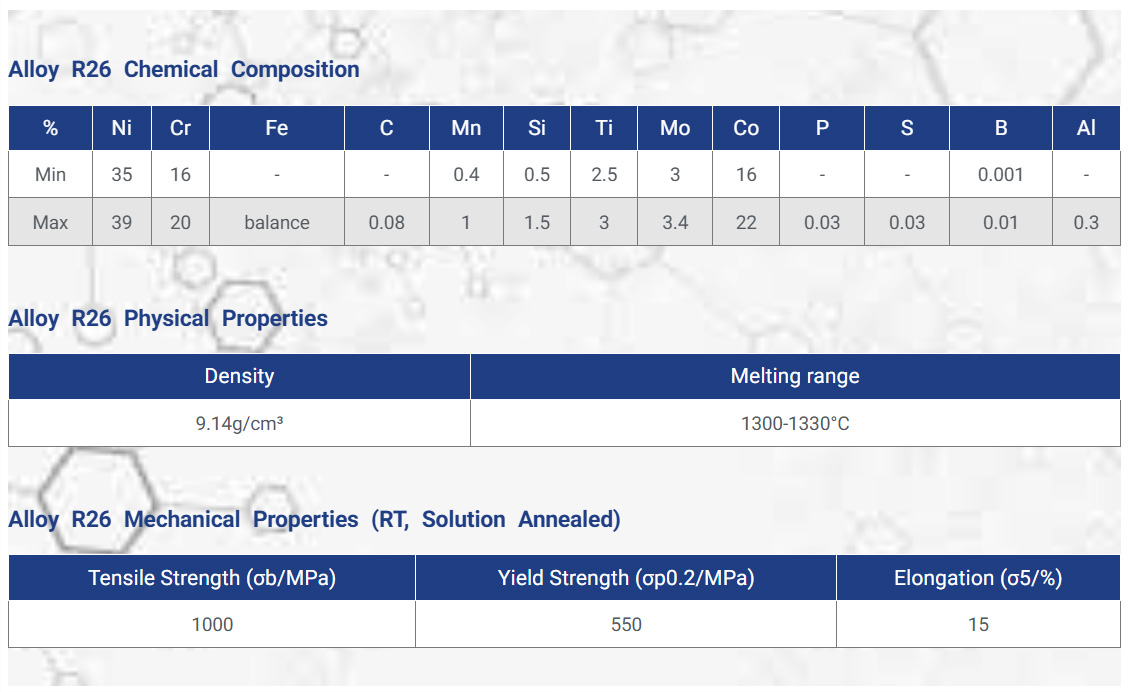

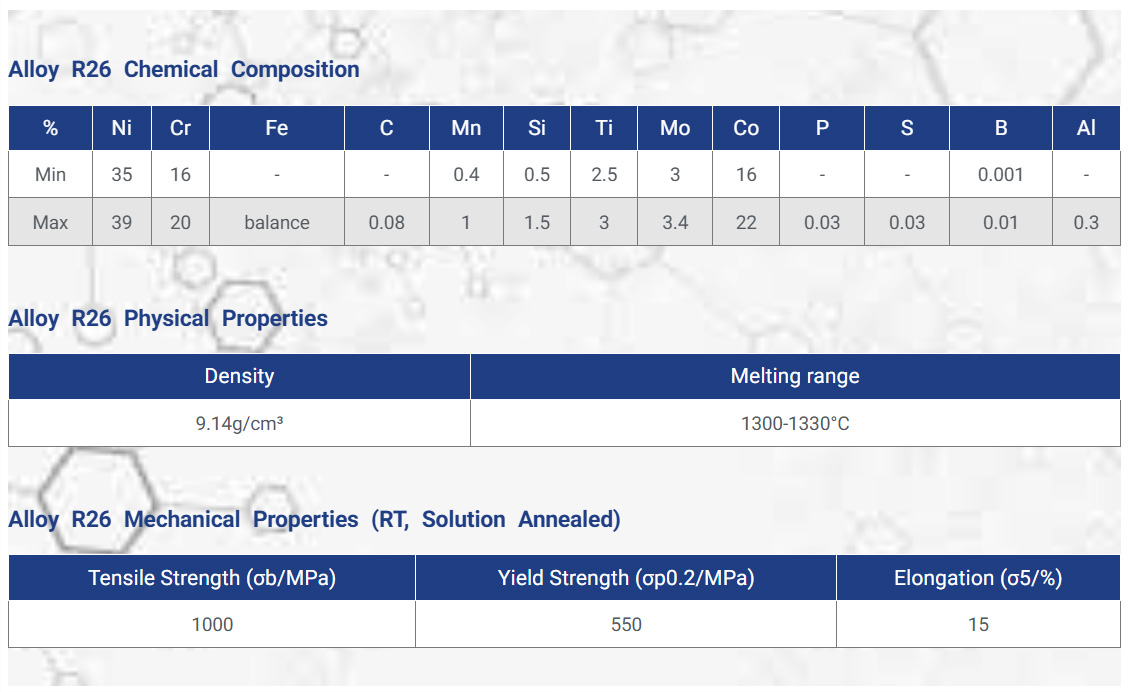

- Excellent High-Temperature Strength: Refractory 26 (R26) alloy maintains superior mechanical properties in high-temperature environments, making it suitable for demanding conditions.

- Outstanding Creep Resistance: The alloy exhibits excellent resistance to creep under high-temperature and high-pressure conditions, ensuring durability and reliability of equipment.

- Good Stress Corrosion Resistance: Refractory 26 alloy has strong resistance to stress corrosion, making it suitable for harsh operating environments.

Applications:

- Oil and Gas Industry: Refractory 26 alloy is utilized in the manufacturing of downhole tools and equipment that can withstand the extreme conditions encountered during drilling and extraction processes.

- Gas Turbines: The alloy is employed in gas turbine components, including combustion chambers and afterburners, due to its ability to maintain strength and resist oxidation at elevated temperatures.

- Aerospace Components: Refractory 26 alloy is used in aerospace applications where high-temperature strength and oxidation resistance are critical.

- Medical Devices: Its biocompatibility makes it suitable for medical implants and devices.