Skip to content

Elgiloy Alloy

Features:

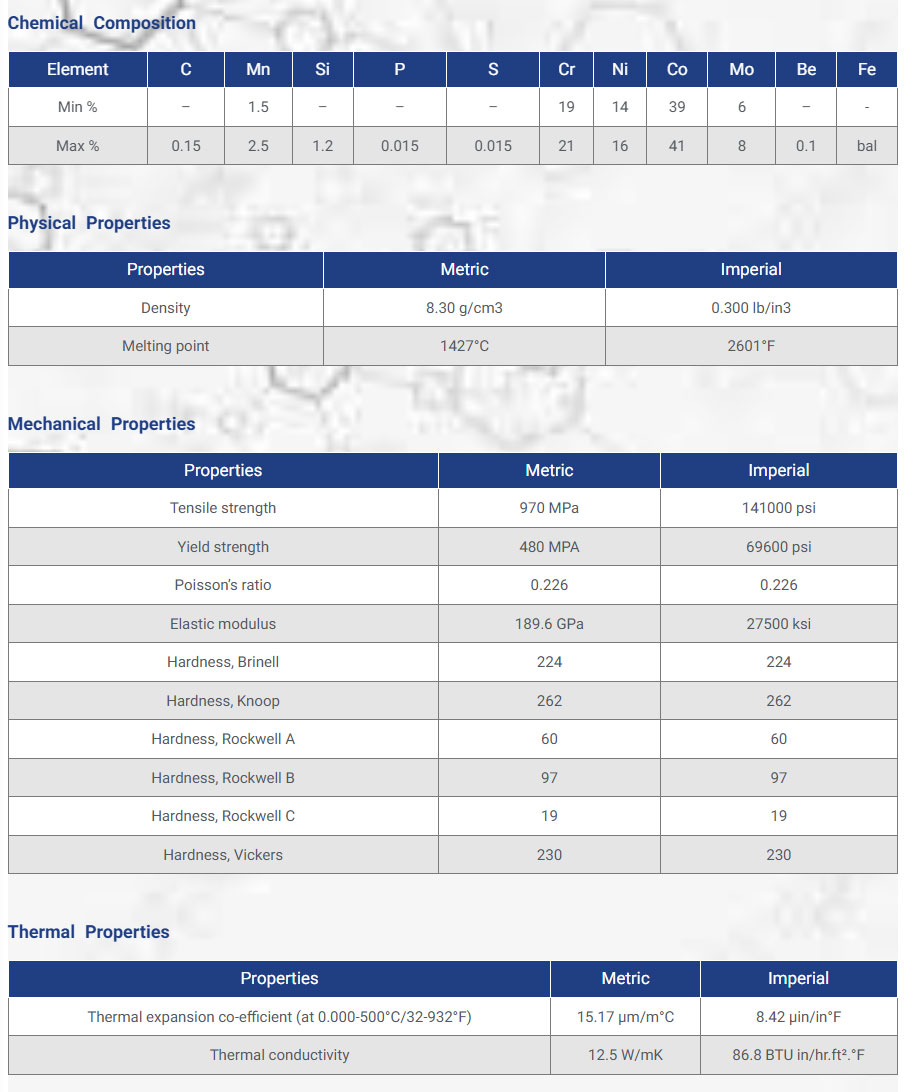

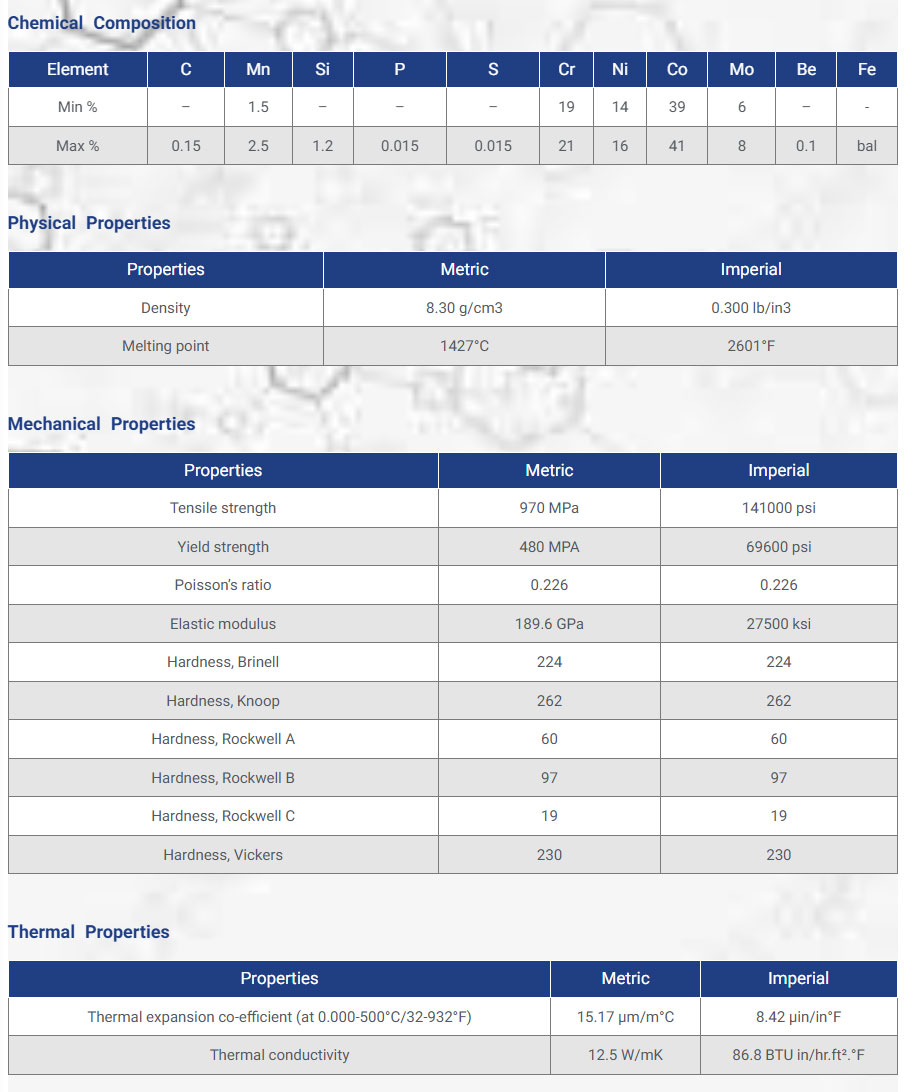

- High Strength: Elgiloy alloy (UNS R30003) is a cobalt-chromium-nickel-molybdenum alloy with excellent strength properties.

- Excellent Corrosion Resistance: The alloy exhibits high resistance to sulfide stress corrosion cracking and pitting, making it suitable for demanding environments.

- Good Fatigue Life: Elgiloy alloy demonstrates good fatigue strength, suitable for applications requiring durability.

- High Elasticity: The alloy possesses a high modulus of elasticity, making it suitable for applications requiring elastic recovery.

Applications:

- Oil and Gas Industry: Elgiloy alloy is used to manufacture high-strength, corrosion-resistant components such as valves, pump shafts, and wellbore tools, capable of withstanding harsh extraction environments.

- Aerospace: The alloy is used to manufacture aircraft control cables, capable of enduring repeated stretching and contracting.

- Semiconductor Industry: Elgiloy alloy is used to manufacture diaphragm valves with high-quality surface finishes, ensuring reliable performance.

- Medical Devices: Due to its biocompatibility and corrosion resistance, Elgiloy alloy is used to manufacture medical instruments such as surgical implants and tools.