Microstructure

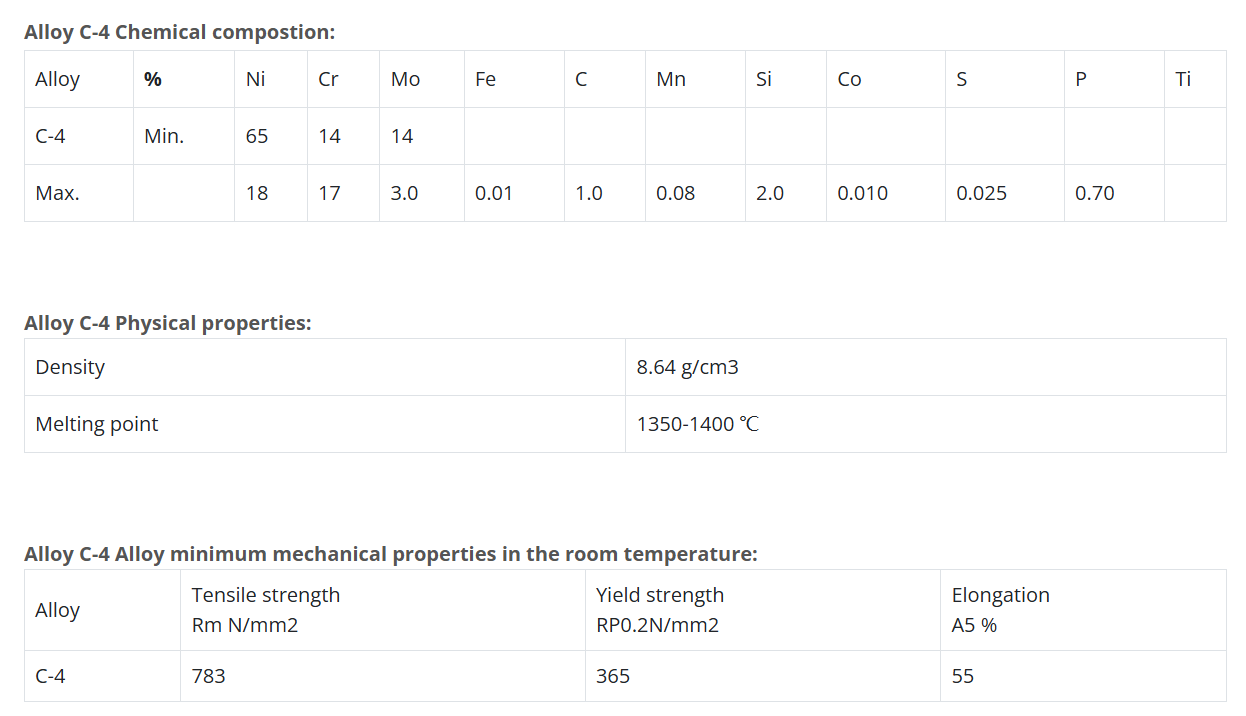

Alloy C-4 is a nickel-chromium-molybdenum alloy with high-temperature stability. It maintains high ductility and corrosion resistance even after prolonged exposure to temperatures in the 1200–1900°F (649–1038°C) range. This alloy also resists grain-boundary precipitate formation in the weld heat-affected zone, making it ideal for chemical process applications in the as-welded condition.

Features

Excellent high-temperature stability, maintaining ductility and corrosion resistance even after aging.

Resistant to grain-boundary precipitate formation, making it suitable for as-welded applications.

Outstanding resistance to stress-corrosion cracking and oxidizing atmospheres up to 1900°F (1038°C).

Exceptional corrosion resistance in hot contaminated mineral acids, solvents, chlorine-based environments, and seawater.

Applications

Chemical processing equipment exposed to hot acids, chlorine, and solvents.

Components in oxidizing and high-temperature environments, such as heat exchangers and reactors.

Seawater and brine systems where corrosion resistance is critical.

Industrial fabrication, including forging, deep drawing, spinning, and press forming.

Welding applications, though oxy-acetylene and submerged arc welding are not recommended for corrosion-sensitive applications. Special precautions should be taken to avoid excessive heat input.

We have products:

Alloy C-4 / UNS N06455 Nickel Alloy 90 Degree Elbow , Pipe Fitting; ASTM B622 / B619 Alloy C-2000 / UNS N06200 Nickel Alloy Pipe; ASTM B574 / ASME SB574 Alloy C-4 / N06455 Nickel Alloy Round Rod; ASTM B575 / ASME SB575 Alloy C276 Nickel Alloy Plate / Sheet; ASTM B564 Alloy C22 / C276 Nickel Alloy Slip On Flange; ASTM B564 Alloy C22 / C276 Nickel Alloy Slip On Flange; ASME SA564 Alloy C22 Nickel Alloy Slip On Flange For Connection; Alloy C22 / C4 / C276 UNS N06022 / N06455 / N10276 Nickel Alloy Flange For Boiler Tube; ASTM B574 Nickel Alloy Steel Alloy C22 / C276 Round Rod / Bar; 3 / 4 Inch Alloy C-4 / UNS N06455 Chemical Industry Nickel Alloy Tube;