904L is an austenitic stainless steel. Compared to 316L, its increased molybdenum (Mo) content enhances resistance to localized attack such as pitting and crevice corrosion, particularly in chloride-rich environments. Additionally, the presence of copper (Cu) provides excellent corrosion resistance across all concentrations of sulfuric acid.

The high alloy content of 904L improves its resistance to chloride stress corrosion cracking, though it remains susceptible under extreme conditions. Furthermore, its low carbon content prevents sensitization during welding, effectively reducing the risk of intergranular corrosion.

Applications include piping systems, pollution control equipment, heat exchangers, and bleaching systems.

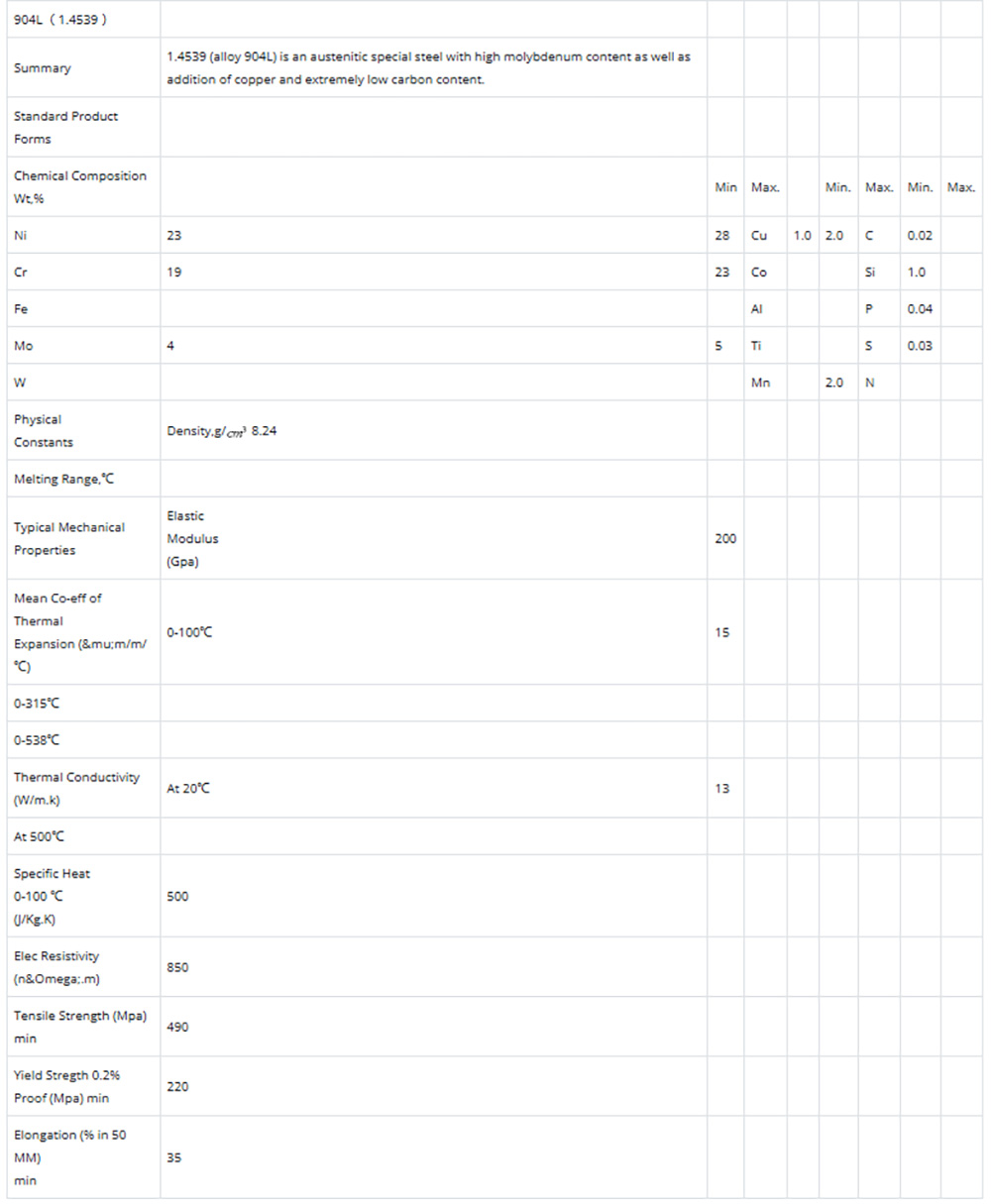

Chemical Composition

- Nickel (Ni):23–28%

- Chromium (Cr):19–23%

- Carbon (C):≤0.02%

- Copper (Cu):1–2%

- Molybdenum (Mo):4–5%

- Manganese (Mn):≤2%

- Silicon (Si):≤1.0%

- Iron (Fe):Balance

We have products:

904L seamless tube steel tube; 1 / 4 Inch Sch10s TP347 / 347H Stainless Steel Welded Multi-core Coiled Tubing; 3 / 4 Inch Sch40s Precision Stainless Steel Tube, TP347 / 347H Seamless Tube; ASTM A182 F904L Flange, Stainless Steel 904L Flanges;