Characteristics

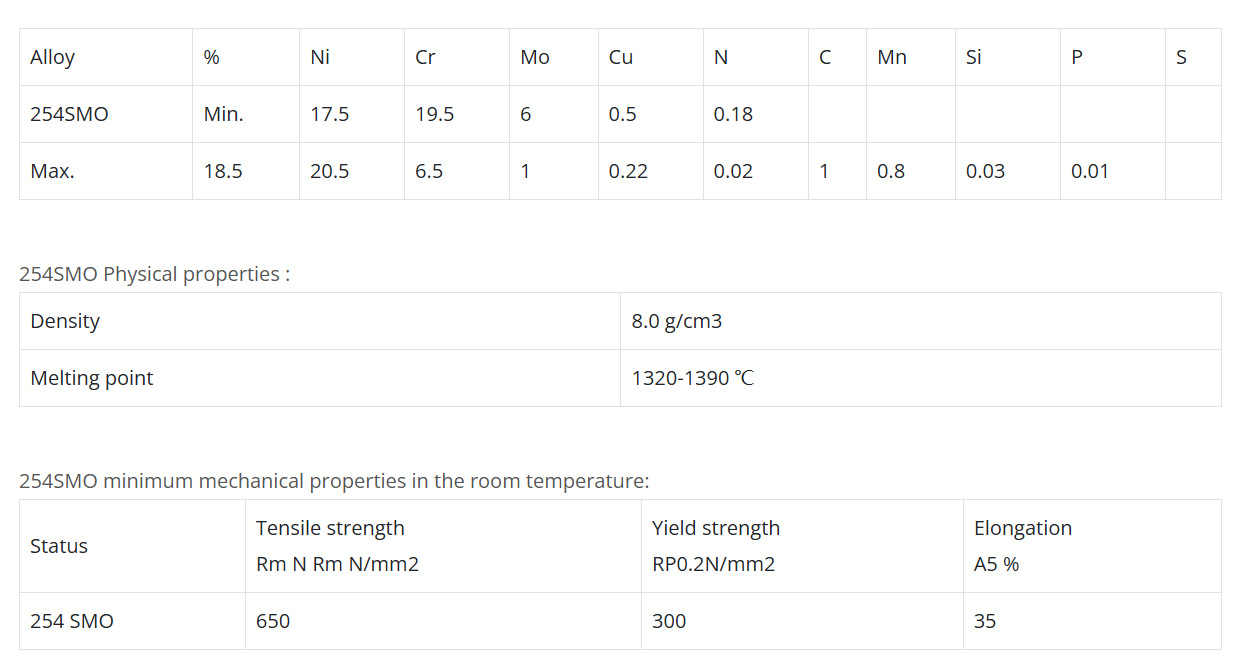

The high concentrations of molybdenum, chromium, and nitrogen provide 254SMO with exceptional resistance to pitting and crevice corrosion. The addition of copper enhances its corrosion resistance in certain acidic environments. Additionally, its high nickel, chromium, and molybdenum content grants excellent resistance to stress corrosion cracking.

Extensive field experience has demonstrated that even at elevated temperatures, 254SMO maintains exceptional corrosion resistance in seawater, surpassing most stainless steels in this regard.

254SMO exhibits outstanding resistance to acidic and halide-containing environments, making it comparable to high-performance nickel-based and titanium alloys used in aggressive conditions such as pulp bleaching.

Due to its high nitrogen content, 254SMO possesses higher mechanical strength than conventional austenitic stainless steels. It also retains excellent ductility, impact strength, and weldability.

The high molybdenum content of 254SMO contributes to its higher oxidation rate during annealing, resulting in a rougher surface after acid cleaning compared to standard stainless steels. However, this roughness does not negatively impact its corrosion resistance.

Metallurgical Structure

254SMO has a face-centered cubic (FCC) structure. To maintain its austenitic structure, annealing is typically performed at 1150–1200°C.

In some cases, trace amounts of secondary phases (χ-phase and α-phase) may form. However, under normal conditions, these phases do not adversely affect impact strength or corrosion resistance.

If exposed to 600–1000°C, intermetallic phases may precipitate at grain boundaries, which could affect performance in specific environments.

Corrosion Resistance

254SMO has an ultra-low carbon content, minimizing the risk of carbide precipitation during heating.

Even after one hour of sensitization at 600–1000°C, it can still pass the Strauss intergranular corrosion test (ASTM A262 Practice E).

Due to its high alloy content, there is potential for intermetallic precipitation at grain boundaries in this temperature range. However, these precipitates do not cause intergranular corrosion in most corrosive environments, making welding feasible without concerns of intergranular attack.

In concentrated nitric acid, these precipitates may lead to intergranular corrosion in the heat-affected zone.

In halide-containing solutions (chloride, bromide, iodide), standard stainless steels such as 316 may experience pitting, crevice corrosion, or stress corrosion cracking. In contrast, 254SMO exhibits superior localized corrosion resistance and significantly slows down uniform corrosion in non-oxidizing acids.

In pure sulfuric acid, 254SMO offers much better corrosion resistance than 316 stainless steel, but slightly lower than 904L (NO8904) at high concentrations.

In sulfuric acid containing chloride ions, 254SMO demonstrates the highest corrosion resistance among stainless steels.

316 stainless steel is unsuitable for hydrochloric acid due to localized and uniform corrosion, whereas 254SMO can be used in diluted hydrochloric acid at general temperatures without significant corrosion risks. However, gap corrosion must be avoided.

In fluorosilicic acid (H₂SiF₄) and hydrofluoric acid (HF), standard stainless steels offer very limited resistance, whereas 254SMO can withstand a much broader range of temperatures and concentrations.

Applications

- As a high-performance, multi-purpose stainless steel, 254SMO is used across various industries:

- Petroleum and Petrochemical Equipment – Including bellows and piping systems.

- Pulp and Paper Industry – Used in bleaching equipment, such as digesters, bleaching towers, washers, and pressure rollers.

- Power Plant Flue Gas Desulfurization (FGD) Systems – Key components include absorption towers, ducts, baffles, internal parts, and spray systems.

- Marine and Seawater Handling Systems – Suitable for thin-walled condensers, seawater desalination equipment, and cooling systems, even when water flow is stagnant.

- Desalination Industry – Applied in salt production and desalination plants.

- Heat Exchangers – Particularly effective in chloride-rich environments.

We have products:

Alloy 254 SMO(6-moly) UNS S31254 6Mo Pipe; 254 SMO Pipe, ASTM A312 UNS S31254 Seamless Pipe;