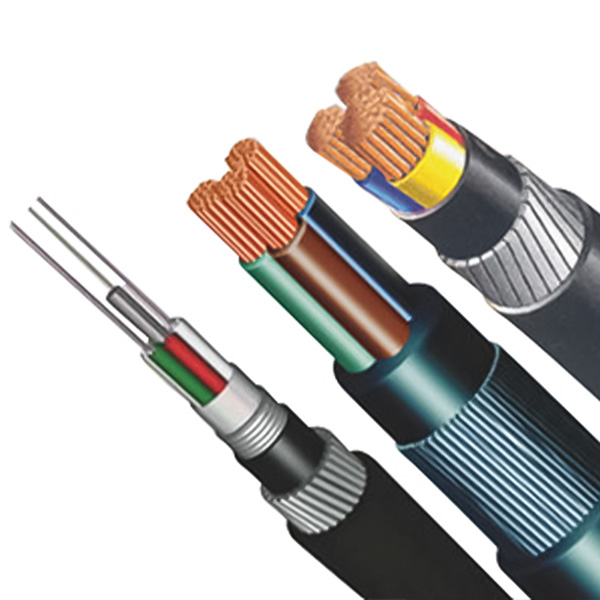

- Steel Wire

Armoring Wire

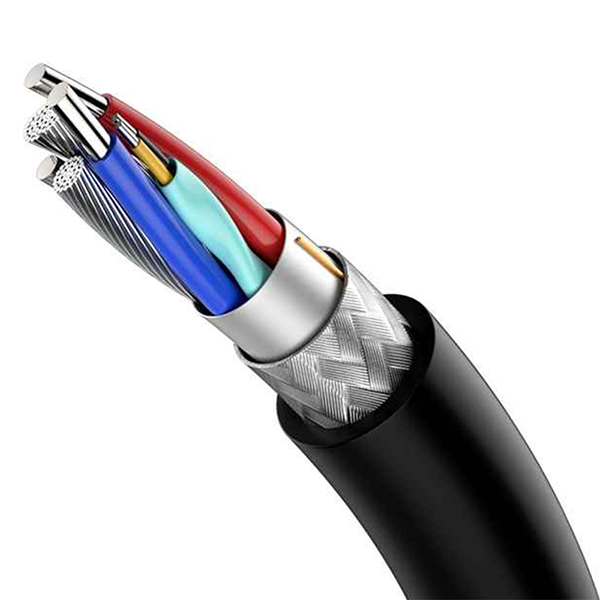

Features

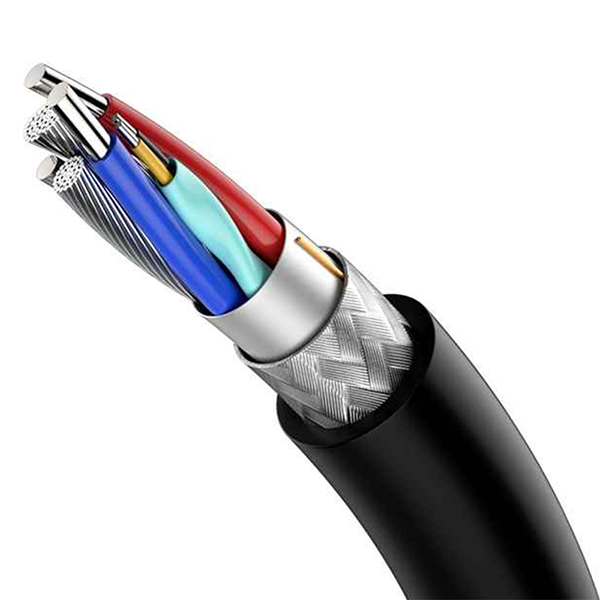

- High-Tensile Strength– Designed to provide superior mechanical protection, ensuring resistance to tension, impact, and external pressure in harsh environments.

- Corrosion & Abrasion Resistance– Manufactured using stainless steel, galvanized steel, and Inconel, offering long-term durability in corrosive, high-moisture, and high-temperature conditions.

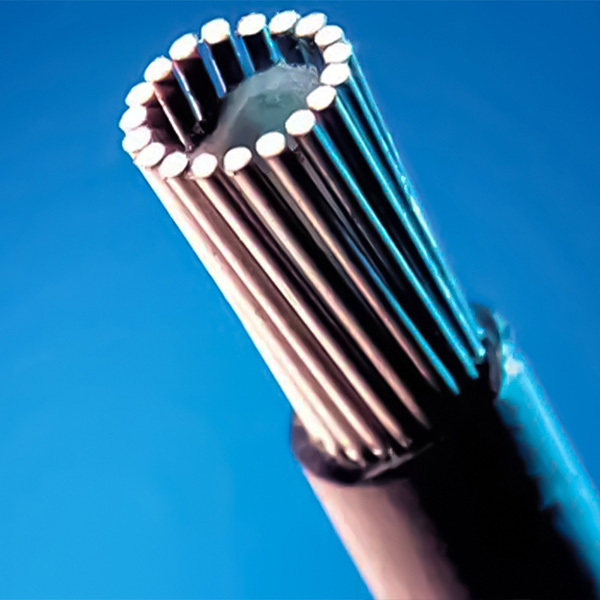

- Precision Engineering– Uniform diameter and coating thickness ensure consistent performance and easy integration into cables, umbilicals, and subsea systems.

- High-Temperature & High-Pressure Resistance– Capable of withstanding temperatures up to 260°C and extreme pressures, making it ideal for downhole, subsea, and industrial applications.

- Flexible & Customizable– Available in round, flat, and profiled designs, with various coatings and materials to suit different environmental challenges.

- Meets Industry Standards– Compliant with API, ASTM, and ISO certifications, ensuring compatibility with global oil & gas, telecommunications, and defense applications.

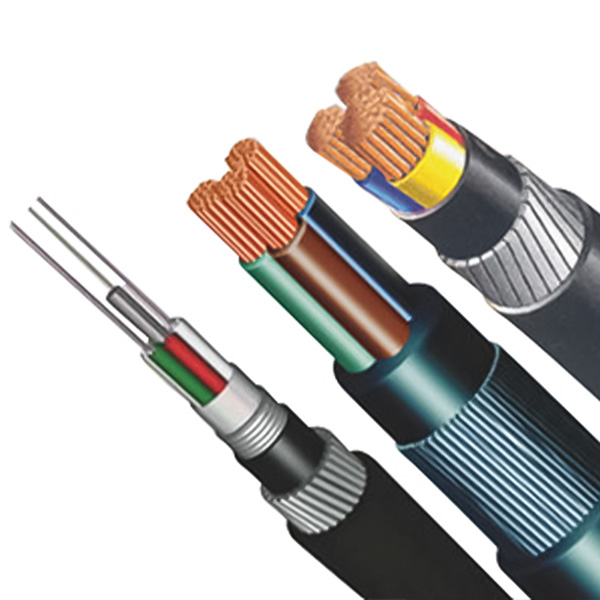

Options

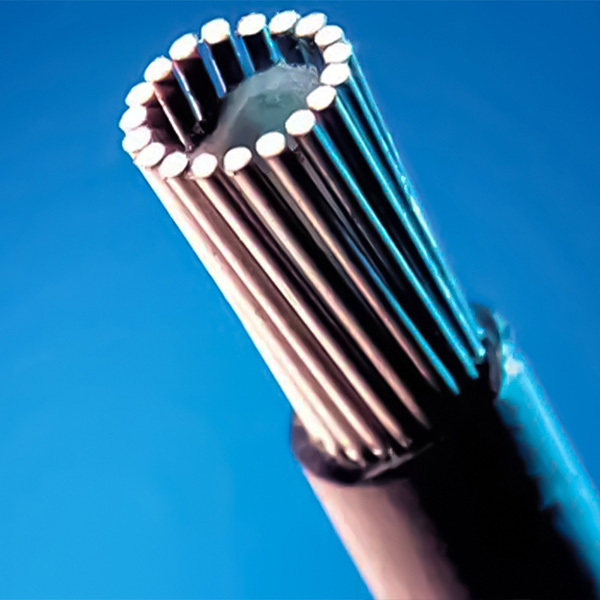

- Material Selection:316L stainless steel, galvanized steel, Inconel, Monel, and copper-clad steel.

- Wire Shapes:Round, flat, and custom-profiled for specific application needs.

- Coating Options:Zinc, polymer, or anti-corrosion coatings

- Diameter Range:Available in various thicknesses, tailored to mechanical load and environmental requirements.

- Tensile Strength Grades:Customizable high-strength and ultra-high-strength options for extreme environments.

- Application-Specific Designs:Engineered for downhole cable armoring, subsea applications, military-grade protection, and industrial reinforcement.

The Armoring Wire series provides exceptional protection, durability, and flexibility, making it an essential component for critical infrastructure in extreme environments.